FCL Series Compressed Air Filters

- Coalescing Filters

Coalescing filters are essential for purifying compressed air, designed to remove:

1. Oil vapour

2. Water

3. Solid particles as small as 0.01 microns

In a typical system, the first filter acts as a pre-filter, removing larger particles and contaminants. This helps protect downstream filters, particularly high-efficiency ones, and ensures the system produces clean, high-quality air.

– Key Features:

Multi-contaminant removal: Effectively captures liquid and solid contaminants, including fine particles.

Pre-filter role: Protects more sensitive filters in the system.

– Considerations:

Moisture impact: High moisture or adsorption conditions can saturate the filter, causing a pressure drop and reduced performance. Ensuring dry conditions and regular maintenance is vital for optimal function. - Activated Carbon Filters

Coalescing filters cannot remove oil vapour, which is gaseous, so activated carbon filters are used. These filters adsorb oil vapour and odours.

– Key Features:

Large adsorption bed: Captures oil vapour and smells effectively.

Gaseous contaminant removal: Designed for gaseous impurities like oil vapour

– Considerations:

Post-dryer installation: Typically placed after an air dryer to ensure dry air, as moisture reduces the carbon’s effectiveness.

Limited to gaseous contaminants: Not for liquid oil or aerosols.

Pre-filtration and maintenance are essential to avoid clogging and maintain efficiency. Regular maintenance and proper installation are crucial for optimal performance.

Key Features

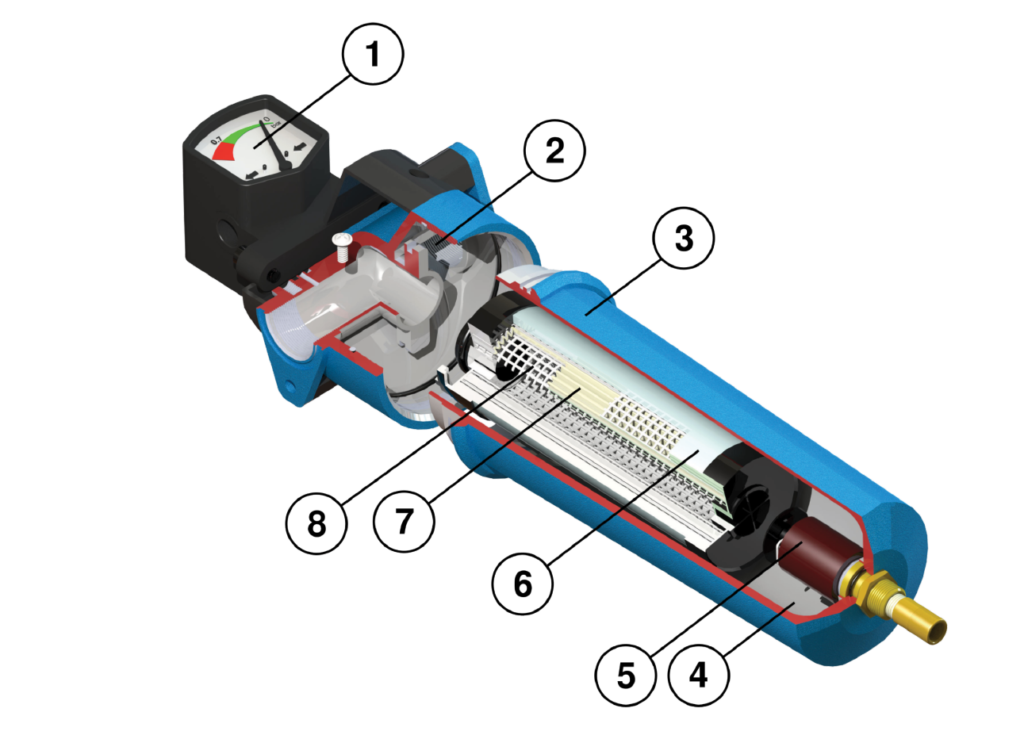

- Accurate Differential Pressure Gauge : Element Replacement Indicator.

- Sealing O-Ring : Durable and robust o-rings to ensure proper sealing and leakage prevention.

- High Pressure Aluminium Pressure Die Casting : The high-pressure aluminum die-casting mold is treated with multiple layers of anti-oxidative coating on both the interior and exterior, ensuring a long-lasting, trouble-free lifespan for the filters.

- Zero Pressure Loss Automatic Drain Valve : Automatic drain valves with manual testing feature designed in EU, built for life-long reliable functioning.

- Robust Construction of the Drain Valve : Drain valve constructed from reinforced, industrial-grade PVC for enhanced durability and performance.

- Advanced Polyester Filtration Felt : Ensures proper protection to the filtration media alongside ensuring optimal flow distribution, proper condensation, and entrapment of water and oil.

- Layered/Pleated Filter Element Design : Innovative design ensures larger filtration surface area, low differential pressure loss and longer lifespan.

- Innovative Stainless Steel Mesh : Rhombus hole stainless steel lattice offers high filtration surface area with negligible differential pressure loss.

To learn more about our range of compressed air filters or to request a quote, please contact our sales team.

We look forward to helping you maintain clean, efficient, and reliable compressed air systems with our high-performance filtration solutions.

We pride ourselves on providing fast, reliable service and delivering filters that you can count on for years of efficient operation. Whether you’re replacing a single filter or outfitting an entire fleet of systems, Full Circle India is your trusted partner for high-quality, customizable compressed air requirements.

To learn more about our range of compressed air filters or to request a quote, please contact our sales team.

We look forward to helping you maintain clean, efficient, and reliable compressed air systems with our high-performance filtration solutions.

We pride ourselves on providing fast, reliable service and delivering filters that you can count on for years of efficient operation. Whether you’re replacing a single filter or outfitting an entire fleet of systems, Full Circle India is your trusted partner for high-quality, customizable compressed air requirements.